Unique Concept: Germany’s landmark Net 0 Disposal of Sludge

Sludge: India’s missed Opportunity

May 14, 2020

Does UK get better Agri-outputs from Shit ? Yes!

September 3, 2020Today we look towards the developed world for technology adoptions and knowledge transfers in almost every field. Out of this, we have seen Germany being a leading force to lend its expertise and its industrial platforms expanding its reach in India both for market capitalisation and helping the countries reach their environmental standards through organisations like German Water Partnership. So we evaluated the German story of net sludge output to learn and hopefully being able to replicate the success stories in India. Upon comparison, it may seem that the total volume of sludge generation is minuscule compared to that of India, the lessons are not only based on treatment capability but to understand the right infrastructure and policy leading up to this success model.

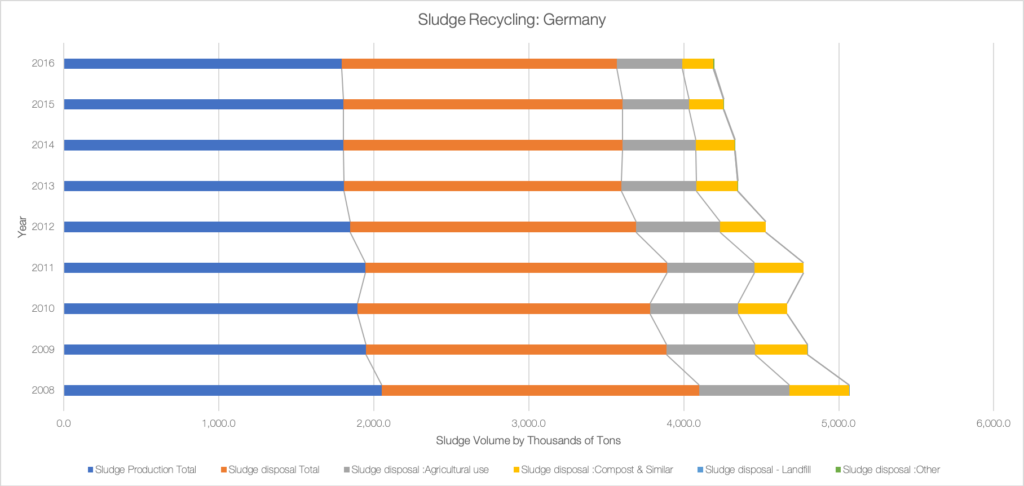

Germany: Sludge recycling breakdown (Total)

Producing around 1,794 thousand tons of sludge in 2016. Germany has been able to recycle almost the entirety of it’s sludge through various channels like Incineration, controlled landfill, compost and so on. The importance of recycling sludge has grown with new legislations like “Verodunung über die Verwetung von Klärschlamm, Klärschlammgemisch und Klärschlammkompost (Klärschlammverodnung – AbfKlärV) which is the P- Strategy 2029/2032 and Verordnung über das Inverkehrbingen von Düngemitteln, Bodenhilfsstoffen, Kultursubstraten and Pflanzehifsmitteln (Düngemittelverordnung – DüMV) which is the Fertilizer regulation setting pollution limits by sludge. The sludge strategy has long dominated the wastewater scene in Germany which lead to some of the leading sludge treatment companies for drying and disposal and are now dominating the market like Thermo-System GmbH with the largest Solar Sludge Drying plant in the world along with more than 200 plants globally. Their total exports in wastewater amounted to approx EUR 977 Million in 2016. Some of these technologies have also made their way to India and we have been fortunate to work with multiple stakeholders to lead these success stories in the Industrial landscape.

Germany 2018 | ||

EU’s biggest sludge Producer | 19.7% | |

Landfill wet sludge | 0% | Exited in 2005. It is the current practice in India |

Incineration | 64% | India does not have any such facilities |

Mono-Incineration | 26% | |

Co-incineration | 25% | |

Cement Industry | 7% | A very small percentage of Industrial sludge is currently being recycled this way in India |

Waste Incineration | 3% | Although, there are solid waste incineration plants they do not take any sludge |

Agriculture | 24% | A very small percentage of Industrial sludge is currently being recycled this way in India. Due to contamination of sewage this is often times not possible |

Landscaping/ composting | <12% | There are no applications like this in India at the moment. |

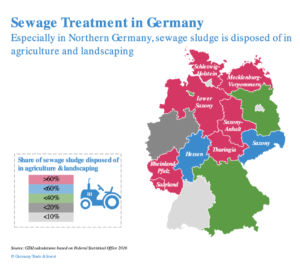

With a greater emphasis on P-recycling, recycling through composting and agriculture is bound to decrease (Over 34% in 2014 ). It can be seen in the map that not every region has the same regulation and based on different local conditions local laws are framed to allow for supporting industries and find synergies. [Disclaimer: Disposal through agriculture is the most widely used route however, it should be noted that unless regulated it can cause several problems like soil contamination due to high levels of nitrites amongst other things. A lot of countries are either completely stepping away from this or controlling it further as seen in the case of Germany. We will be discussing this further in our other country case studies]

German Sludge Agriculture and Landfill Map

The increase in Incineration reuse provides the country with a great alternative to fossil fuels, provides clean energy and also fulfils the industry demand. The development of these industries in Germany has not been fast paced. It has taken time and required constantly revised regulation to meet the new standards. Such regulation with strict enforcement has led to the development of these industries that not only ensure environmental compliance but also providing a new platform for innovators and entrepreneurs.

Wet sludge landfilling is a very archaic practise that has been banned in most countries and yet, India practices this openly thought the country. This not only poses as a public health risk but also shows a missed opportunity in the India market as seen by the successful implementation of such models in Germany.

India has a huge dependence on coal and fossil fuels with the Government’s progressive agenda towards clean energy and sanitation there could be great synergies to be realised in the space allowing India to propel towards the next step it’s journey for a more sustainable future. Concepts like P – recycling may be a distant future but investments in waste conversions for RDF and Agriculture could reduce our morbid dependency on chemical fertilisers that plague our fields and imported fossil fuels that burden the country with debt.

GWP and similar organisations have been very active in India to push for these concept adoptions however, due to a clear lack of infrastructure in both monitoring and treatment, we often find ourselves helpless. We should encourage our industries and impose these regulations for recycling and impose fines and surcharges for disposal. Landfilling sludge mixed with other kinds of waste leads to destruction of value. The potential value here lies in the millions