Multi Layer Mesh Belt Dryer

Process

The Multi layer mesh belt dryers is a very versatile equipment which offers various options for heating mediums for processing whilst delivering value by providing a drying solution for a spectrum of products in both process and waste.

A Feeding mechanism is designed to transfer the material from storage shed to the drying chamber and spread over the entire width of the machine uniformly.

Once, the material is feed to the drying chamber, the material is transferred throughout the entire length of the drying surface with the help of a specially designed Stainless steel belt to allow for better air circulation.

The equipment is capable of handling varying temperatures from 65-160 degrees Celsius. Along with the speed of the belt to transfer the material from end to end of the drying chamber. This offers a wide range of applications for different products.

Working principle

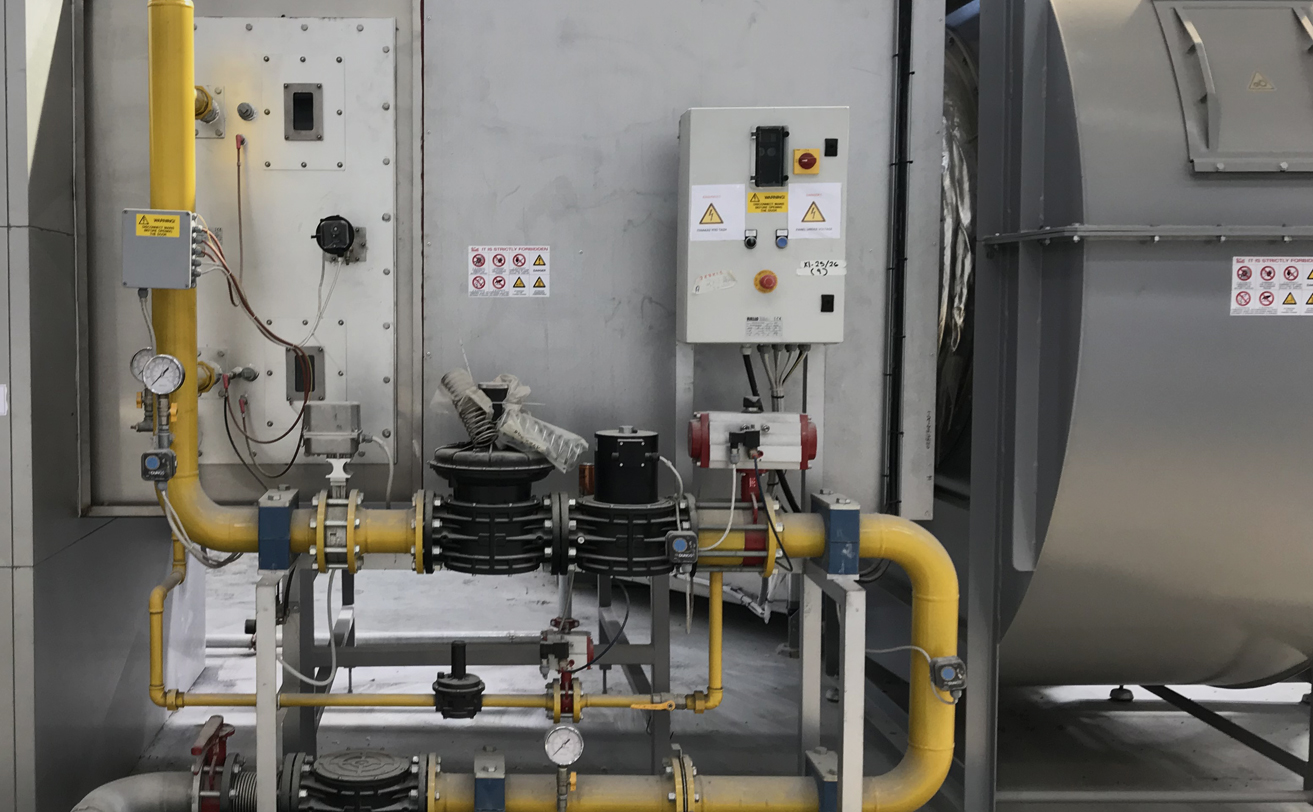

As the product moves through the different layers of the dryer, It looses it’s moisture and dehydrates. The air travels upwards through the specially designed belt and the exhaust fan sucks the humid air from the chamber and exits in to the atmosphere.

The dried material is delivered out of the chamber through the last belt and on to the further material handling system.

This Is Why

We Should Use Multi Layer Mesh Belt Dryer

Principles of Air Management

We use the principles of air management for optimise the drying efficiency. We provide larger air volumes to dissipate the effect of dependence on temperature.

Consistency

Dryer configuration can be completely adapted to the material. Speed and temperature of the dryer can be adjusted as per the material requirement.

Temperature Control

The drying temperature can be adjusted from 65-160 °C.

Highly Efficient

The machine is modular in nature and hence offers easy and low maintenance. The machine is very robust and offers longer operational hours.

Fully Automated

The machine can be completely automated to design for the material and site.

Energy optimization

Energy optimization options like waste heat recovery systems.